Barbie T-Bird Rocket Car

Welcome to my evil lair, I mean my evil water rocket page. It all began last spring (1999) when my friend Frank Kaplan said, "Hey, you oughta search for water rockets on the web". Being a web savvy kind of guy I did, and discovered the wacky world of water rockets. With 2 part epoxy and anything involving high pressure being some of my favorite things I was deeply intrigued. Scouring every site I could lay my HotBot on I kept gravitating back to Gary Ensmenger's rockets, particularly his Anti Gravity Vortex Rockets. I liked the crash-worthy, rubber band attached, cold formed, lexan fins. And I liked the inherent stability of a "stemmed" rocket. The detachable stem and fin design got me thinking about a modular design where fins, stems, varying number of bottles, and even a parachute device could be easily configured with no tools. To this end I embraced double ended bottles, and created the coupler shown below.

Double ended bottles

| You make double ended bottles by cutting off the bottoms of 2 liter bottles with a razor knife, curling the edges by pressing the cut end on a heated-on-a-stove-top circular saw blade, then very briefly dipping about 1" of the the curled end of the bottle in boiling water to shrink it, and finally using PL Pemium adhesive to glue two curled bottles together using a sleeve of another bottle. Then use filament packing tape to reinforce the walls of the rocket. My rockets repeatedly withstand 140 psi of air pressure! |

Coupling device for double ended bottles

| This coupler involves drilling holes in two bottle caps and epoxying them into a short length of 1" pvc thinwall pipe. They're cheap and easy to make, and you can easily chain together many double-ended bottles, with no tools. Of course this depends on double ended bottles. |

The Launcher Details on the launcher here

My launcher has two "towers" so to speak, one that uses the Japanese-favored, quick disconnect garden hose fitting, the other being the standard design where a 3/4" pvc pipe fits up into a bottle neck and a rubber O-ring gasket forms a seal. On mine an aluminum collar holds the bottle down and is pulled off by a string.

I found that a high pressure bike pump works great for water rockets, mine has a pressure guage built in that goes to 140 psi and we routinely max it out, heh heh heh. About 25 feet of coiled plastic tubing connects from the towers to a pvc, t-shaped assembly with, get this, both Schraeder and Presta valve stems. High pressure bike pumps usually fit Presta valves, but I figured if my good pump broke it'd be great to be able to use a Schraeder valve-type pump too. (Schraeder valve stems are the kind used throughout the US on car tires). The great thing about the Presta valve stem is that it's easy to use as an abort-the-launch mechanism for releasing bottle pressure. I have two little brass valves that allow independent pressurizing of one tower vs. the other, or if you're in a really crazy mood you can have simultaneous launches on both towers, or try to hit one rocket with another (yikes!). One refinement of the quick disconnect garden hose tower is the use of a retractable, stainless steel tube that serves as a guide for the first foot or so of the rocket's travel.

Well, enough of the science of it all eh?

From left to right, number 1 son Max, nephews Tommy and Joel on a beautiful day in the Northwest, at Pacific Beach, WA. Note the coupled bottles on the "big" tower, and the cylindrical finned smaller rocket on the quick disconnect garden hose tower.

Schlepping rocket paraphenalia out to a safe launch zone. There was an onshore breeze this day and we had to walk quite a ways out towards the water to avoid having rockets come down in the trees.

These photos show the column of water left behind during the launch. Because of the way the wind was blowing we ended up getting wet from the blast with every launch. Having the rocket spew water all over us actually led to a more intimate experience.

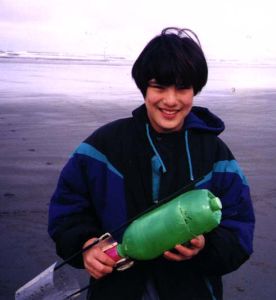

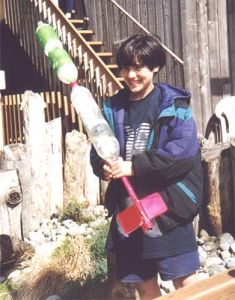

The cylindrical finned rockets with no parachute always crash hard. Spectacularly I might add. I basically abandoned this design and now use the quick disconnect garden hose tower exclusively for water rocket powered cars. Nephew Joel holds the ill-fated rocket.

Male bonding while filling a large-ish rocket. These babies use up a lot of water, and take a long time to pump up. Note the stainless steel guide tube extending out of the other tower. Note also how easy it is to fill double ended bottle rockets, just stick the funnel in the top, pour, then cap.

Retrieving rockets. The beauty of these stemmed rockets is that they need NO parachute. They float down sideways, consistently, in a graceful slowly wobbling kind of way.

Mike "The Gantry" Amundsen holds a mondo rocket up during launch. It was so heavy with water at launch it wouldn't stay standing by itself. This one uses a flourescent light tube protector as one of it's sections. It took gallons of water to reach the 40% optimal fill point, and was wildly impressive at launch. FOOM!!! Mike averted his eyes above the 60 psi level so as not to be blinded in the event of a catastrophic failure at launch. Ironically later that year after my number 2 son Evan stepped on that tube in the basement, it exploded on the pad with a cannon like sound that shredded the plastic. In retrospect this was pretty stupid thing to do, but naturally lots of fun.

Mike on the strings, Steve pumping, the boys look on.

As it turns out we didn't walk quite far out enough away from the trees. This shot shows a rocket falling out of a tree after fishing it out with a couple of sleeved-together windsurf masts.

Nephew Joel was happy to have the rocket back.

The water rocket troops arrive on a canoe trip.

Take me to see water rocket powered CARS.