Jim's home | Trimaran home | This boat's home

Center hull and cross beam (vaka and aka)

Ideas

Choosing an aka

Seating

Attaching the aka

Brackets for foils and akas

Ideas - Return to top

In the beginning, I bought a vintage 18 foot Solcat catamaran off Craigslist, complete with trailer from a guy in Lebanon, OR for $300. The sails and standing rigging looked in good shape, and the hulls looked fine too. Solcats are known for having relatively low volume for their hulls. I thought this'd be OK given the idea was to be 2 feet above the water on hydrofoils anyway. My friend Paul Gallagher (here forward to be known as "Paul") had a Hobie 18 catamaran and offered to sell me one of his hulls. I compared the two. The Solcat's was lighter being built of Airex foam core vs. the Hobie's fiberglass and resin only, and its top surface was symmetric compared with the Hobie's which had curved akas. I went for the Solcat hull.

Interesting comparing the two. Note the difference in the fore-aft spacing of the akas.

The Solcat's transom was closer to vertical too, which I thought would make crafting a foiling, retracting rudder easier.

The Hobie's bow was more upswept, which may have been a good thing.

Choosing an aka - Return to top

I bought a mast from a wrecked French sailboat, and cut it down to 22 feet in length. That makes for a 1:1.22 aspect ratio. Here's the mast set into the molding for the Solcat's original forward aka.

A view from the stern.

It turns out the mast was twisted. My guess is that the twist is at least 10 degrees if not more. I tried twisting it back with what tools I had, but it wouldn't twist at all. No twist is what I wanted, and I thought I could shim things as needed to account for the twist. Kind of like remodeling an old house where nothing is level, plumb or square.

My jig for attempting to straighten the mast.

Here's where I wanted the aka to be mounted, in front of the mold for the original aka. I have the jib travelers set on to the aka here, and the mast base set in place.

I took the trampoline track off of the extra hull and mounted it onto the other side of the hull, so each tramp could be used on each side of the hull.

A close up of the jib travelers and the mast base.

One of these brackets was mounted on the inside of each hull. I mounted both on the one hull to catch the forestay.

Seating - Return to top

Here are the tramps partially installed, along with the Solcat's original forward aka. Was experimenting with an aluminum strut between it and the bigger aka.

Ropes temporarily stretching the tramps tight. I've since had small sections of forward tramps made.

Was experimenting with a traveller for the main sheet, but have since decided to go with a wishbone boom, so no need for a mainsheet traveller.

A mounting strap for cables that stabilize the akas. It's since been removed but as of this writing will likely come back.

Tangs shown at end of rear aka, to connect a cable from the transom to the end of the aka.

Attaching the aka - Return to top

The area below the new 22 foot aka needed some reinforcement. Shrouds (water stays) would go from the side of the center hull (vaka) to near the end of the aka. This to handle the upward stress on the aka when foiling. Divinycell bulkheads are shown here, with plywood and fiberglass.

More reinforcement.

A 1" x 1/8" stainless steel strap spanned the hull horizontally here, with angle aluminum helping attach it to the bulkhead. The ends of the strap poked out of the sides of the vaka to form tangs for the water stays.

A view of the bulkhead, with stainless steel bolts attaching the strap and angle.

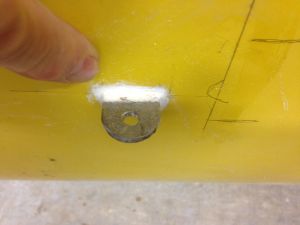

The rounded, drilled end of the stainless steel strap extending through the outside of the vaka, with 5200 sealant used.

An inside view.

Here's the fiberglass/epoxy molding that will hold the aka. Lots of layers of glass in this.

The hole no drilled for the bolt that holds the mast base in place.

Side view.

Close up of the hole. The black surface is rubbery pond liner material glued to the fiberglass molding.

The mast base.

This is a cast aluminum piece, shaped to fit the Solcat's akas, not the French sailboat's mast.

I had to add thickened epoxy to the bottom surface of it to make it conform to the French mast. Seems to fit well now.

Brackets for foils and akas - Return to top

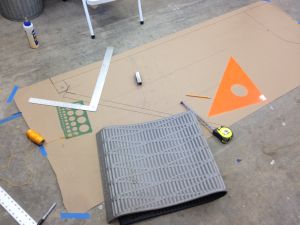

I made a full scale drawing for fabricating the folding stainless steel brackets that would deploy the surface piercing foils to their 45 degree downward angle. They hinge in the middle so the foils can be retracted for sailing in shallow water.

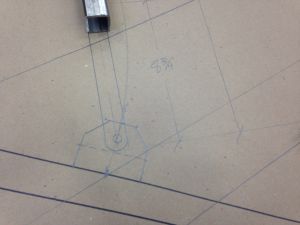

A close up of what the end bracket looks like where it bolts on to the foil.

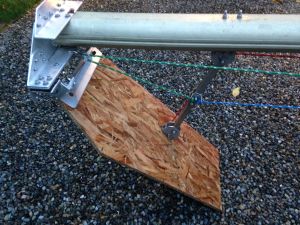

Here's a placeholder OSB foil bolted on to the aluminum brackets at the end of the aka, with the stainless steel folding strut in the the deployed position.

And here's what it looks like retracted.

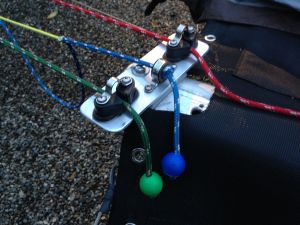

Here are the control lines for deploying and retracting the foils.

The red line retracts, the green line deploys, and the blue line folds the strut so you can pull the red line. Cam cleats with fairleads are for the red and green lines. It worked well with this mockup. But in actual use I had to add blocks to gain mechanical advantage since it takes considerable effort to movie the foils up and down in the water. Once I do so they worked like a champ.

What it looks like from the cockpit.

Deployed. I can tell this is going to be fun.

Another view of it deployed.

And retracted.

Continue